Manufacturing of Molded Rubber Parts for Wiring Harness, Motor,

Anti-Lock Brake System and other interior excluding product design.

Our molded rubber parts serve critical functions across automotive systems

Trusted supplier to major automotive manufacturers and tier-1 suppliers across Asia-Pacific.

Strategic location with skilled workforce, competitive costs, and reliable logistics networks.

Manufacturing based on client specifications – we bring your designs to production reality.

Manufacturing of Molded Rubber Parts for Wiring Harness, Motor,

Anti-Lock Brake System and other interior excluding product design.

Our molded rubber parts serve critical functions across automotive systems

Trusted supplier to major automotive manufacturers and tier-1 suppliers across Asia-Pacific.

Strategic location with skilled workforce, competitive costs, and reliable logistics networks.

Manufacturing based on client specifications – we bring your designs to production reality.

CERTIFICATION PREVIEW

ISO 14001:2015

Cert. No.: 01 104 075076

Valid until : 06/11/2027

CERTIFICATION PREVIEW

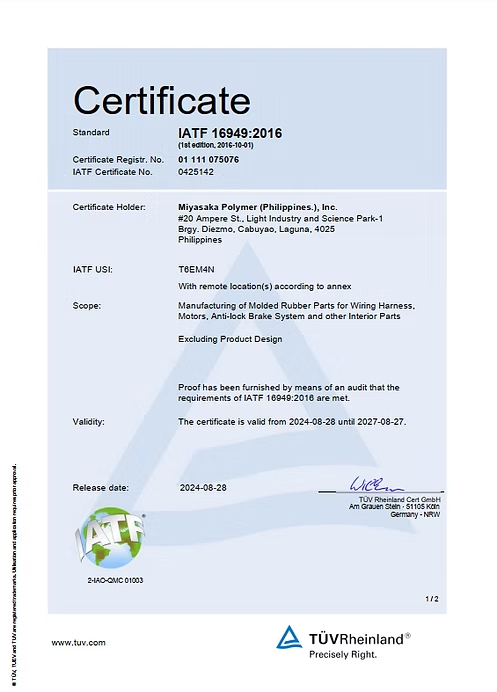

IATF 16949:2016

Cert. Registr. No.:01 111 075076

IATF No:0425142

Valid Until :08/27/2027

CERTIFICATION PREVIEW

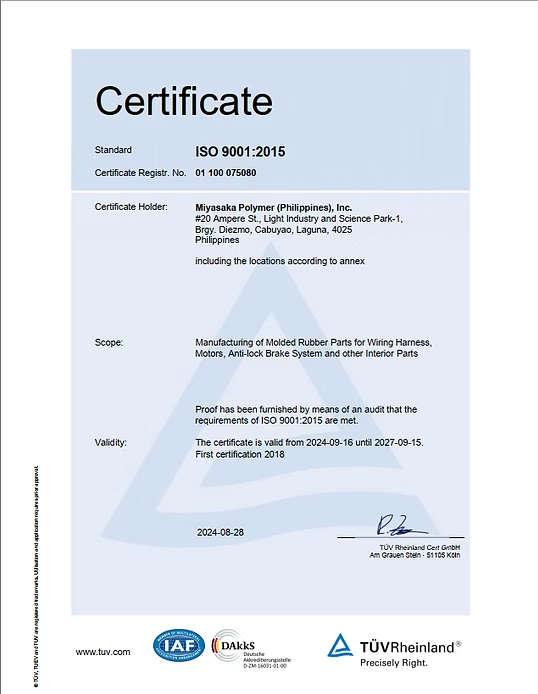

ISO 9001:2015

Cert. Registr. No.: 01 100 075080

Valid until: 09/15/2027